Who are we?

Reliable and Proven

Expert-level technology

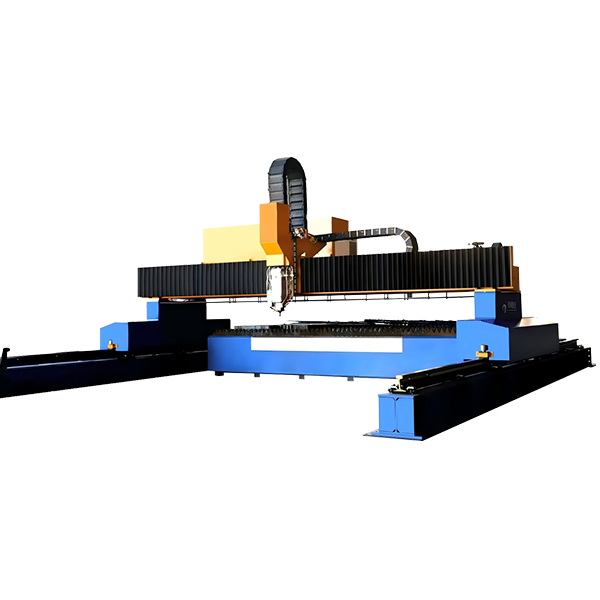

All of our laser products

Laser Product Application Fields

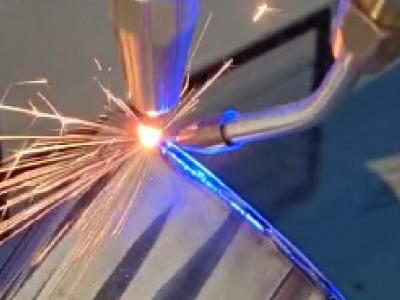

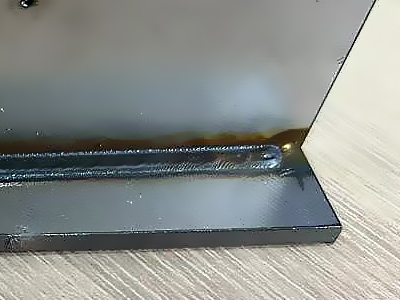

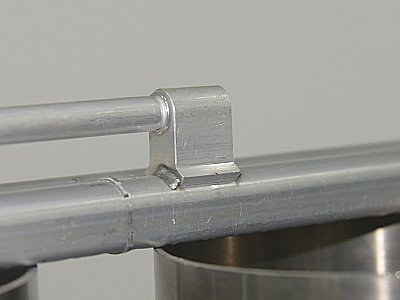

Handle held laser welding machine

Product Applications

Multiple Welding Methods

Suitable for butt welding, lap welding, internal and external corner welding, arc welding, irregular shape welding, etc.

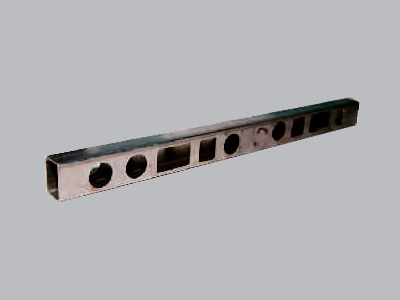

Applicable Materials

Carbon steel, stainless steel, high-strength steel, aluminum, copper, alloys, etc.

Application Fields

Sheet metal, molds, chassis, water tanks, kitchen and bathroom products, hardware lighting, billboards, doors and windows, home appliances, etc.

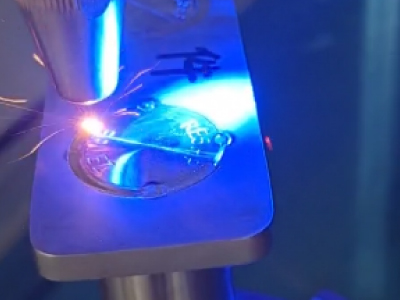

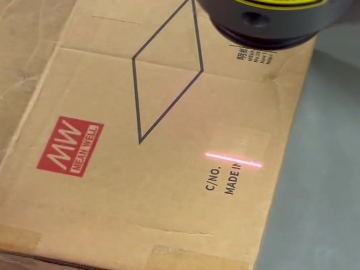

Laser cleaning machine

Product Applications

Laser Cleaning:

Pulse Cleaning, Continuous Cleaning, etc.

Applicable Materials:

Metals: Oxides such as rust and welding scale. Composites: Coatings, paint layers, etc. Stone/Concrete: Oil stains, grease, etc. Wood, Paper, Rubber & Plastics, and other materials.

Application Fields:

Industrial Manufacturing & Mold Maintenance;Architecture & Stonework;Microelectronics Industry;Automotive & Rail Transportation.

Our Full Suite of Services

We have a professional technology R & D team and an efficient after-sales team.

Custom Fabrication

Designed to meet every project’s unique demands.

Lifetime maintenance

Maintenance services will be provided for a lifetime, and only the cost of accessories will be charged.

After-sales support

We have a complete after-sales service system, providing fast after-sales service and tech support.

24/7 Online Support

We provide 24 - hour online support, 7 days a week.

On-Time Delivery

Reliable timelines for every order, every time.

Custom Solutions

Custom-tailored approaches designed for your needs.

Call us for any inquiry

+86 13098839972

More faq us

FAQ about laser machines

What are the advantages of fiber laser equipment compared with traditional laser equipment?

Fiber lasers have a higher photoelectric conversion efficiency (which can reach over 30%), lower energy consumption, a longer lifespan (more than 100,000 hours), a smaller volume, and are maintenance-free (there is no problem of optical lens contamination). They are especially suitable for high-precision and high-speed processing scenarios.

How should the laser wavelength and power of the equipment be selected?

The common wavelength is 1064nm (it is the first choice for metal cutting and welding). The power should be selected according to the thickness of the material (for example, 500W – 1kW is suitable for thin stainless steel sheets, and more than 6kW can cut carbon steel with a thickness of over 20mm). Our technical team can provide free suggestions for model selection.

What precautions should be taken during daily operation?

1.Ensure that the working environment is clean to prevent dust from affecting heat dissipation.

2.Regularly check the cooling system (the recommended water temperature is between 20℃ and 25℃).

3.Avoid running at full load for a long time (it is recommended to operate at a load of less than 80%).

How can I get after-sales support when the equipment breaks down?

We offer full – cycle fault response services:

1. Instant response. 24/7 technical support hotline: +86 13098839972

2. Online customer service (supporting Chinese, English and Russian,etc)

3. Remote diagnosis (video guidance)

What is covered by the warranty?

Long-Term Warranty

Laser Source: 2 Years | Complete Machine: 1 Year

Lifetime Maintenance

Lifetime repair service with only cost charges for replacement parts

Lifetime Value-Added Services

Free technical consulting, process optimization and software upgrades